How Easy is It to Crush Granite

With the development of the stone crushing machine, more and more types of granite crushers are sold on the market. Different types of granite crushers are suitable for different crushing stage, have different finished product sizes and different prices

This article will compare the granite crushers on the market and help you select the most suitable granite crusher.

The features of granite

Nature granite is a kind of igneous rock, also known as acid crystalline plutonic rock. It is hard (6-7 on the Mohs scale) and brittle, with a high silicon content, making it a difficult material to break.

After crushing, granit stones of different sizes can be used a building aggregates. Due to its excellent performance, granite aggregates are widely used for driveway gravel, walkways, drainage solutions, road base, etc.

The physical property of granite

| Physical characteristics | Numerical value |

| Density | 2790-3070 kg/m3 |

| Compressive strength | 1000-3000 kg/cm2 |

| Water absorption | 0.13% |

| Quartz content | 10% to 50% |

| Moh's hardness | 6 to 7 |

| Elasticity modulus | 1.3-1.5x106 kg/cm2 |

Applications of granite sand and gravel aggregates in different sizes

Applications of granite sand and gravel

- 80-150 mm (gravel in over-large size): mainly used for large water conservancy and hydropower construction

- 40-80 mm (gravel in large size): mainly used for the construction of road, road base, and railway

- 20-40 mm (gravel in medium size): mainly used for civil construction

- 5-20 mm (gravel in small size): mainly used for large concrete buildings

- Under 5 mm (sand): used for various building and road construction project

Common types of granite crushing equipment

Granite jaw crusher Get Latest Price

Granite jaw crusher

Feeding size: ≤1500 mm

Discharging size: 25-350 mm

Capacity: 1-2200 t/h

Granite jaw crusher is a new type of jaw crusher, which is developed by Fote Heavy Machinery based on the characteristics of granite. It has a novel structure and a reasonable layout.

Video of granite jaw crusher

The large crushing force and strong pressure resistance allow it to crush materials with compressive strength of 320 MPa.

It is often used as the primary crushing equipment of granite and the large granite can be crushed to a particle size of less than 100 mm. During the crushing process of granite, a piece of granite is crushed by shearing, breaking, splitting and extrusion which makes the finished product more solid.

During the working process, granite jaw crusher runs stably with lower faulty rate and longer service life. It also has the advantages of small investment, large crushing ratio, wide applications, and high working efficiency.

Customer feedback:

Fote granite jaw crusher has stable performance, low failure rate, and long service life, which saves me a lot of operation and maintenance costs.

Granite cone crusher

Feeding size: ≤1500 mm

Discharging size: 25-100 mm

Capacity: 1-700 t/h

Get Latest Price

Cone crusher adopts the principle of inter-granular lamination to crush the granite, replacing the traditional single particle crushing principle.

It not only realizes the selective crushing of materials but also significantly increases the product fines ratio and cube content, greatly reducing the needle-like materials and the wear on the parts.

In addition, the cone crusher also uses a modular design. Through the replacement of the cavity type, it can realize the conversion of coarse, medium and fine crushing, improve the production efficiency, and also meet the large production demand.

In response to the call for environmental protection and to solve the dust and noise pollution, Fote Heavy Machinery has made the following improvements on the original basis of cone crusher:

It has a complete dust collection and dust reduction device

The discharge port, screen and key parts of the cone crusher are equipped with a spray system, which can humidify the dry material, increase its weight, and effectively inhibit and reduce dust pollution.

A complete dust collecting system is arranged in the crusher side to effectively reduce dust pollution from the source.

It is equipped with advanced noise dilution device

The dilution of noise first passes through the environmental protection layer built into the cone crusher. This wear-resistant buffer layer not only dilutes the noise but also protects the machine and reduces the noise around workers.

Customer feedback:

The product processed by this equipment has a good grain shape, which broadens my aggregate market and brings me many high-quality customers.

Granite impact crusher Get Latest Price

Granite impact crusher

Feeding size: ≤800 mm

Discharging size: 10-80 mm

Capacity: 30-800t/h

The impact crusher has a compact structure, strong rigidity, safe operation and reliable production, and is suitable for medium and fine crushing.

Video of granite impact crusher

However, the hammer and counter-attack plate of the impact crusher are easy to wear. Especially when crushing hard rocks such as granite, the wear is more serious and the wear parts need to be replaced frequently, which not only increases production costs but also extends downtime.

Customer feedback:

The impact plate of granite impact crusher supplied by Fote is very wear-resistant, saving a lot of maintenance costs for me.

Granite sand making machine Get Latest Price

Granite sand making machine

Feeding size: ≤50 mm

Discharging size: 2-20 mm

Capacity: 120-650t/h

The sand making machine is the common equipment for making granite sand, and it can process granite into three kinds of aggregate products of 0-5mm, 5-8mm, 8-12mm and 12-15mm.

The granite aggregate processed by the sand making machine has a solid shape, strong adhesion and long durability, and is widely used in highways, railways, bridges, airports, real estate and other fields.

If the material requirements are low, the jaw crusher and the cone crusher are required to crush the granite. Or else, the sand making machine should be added for the final shaping of the material.

Customer feedback:

The granite sand making machine is stable in operation. the failure rate is very small, the output of sand making machine is huge, and the finished products are uniform with cubic shape, which is favored by downstream users.

Semi-mobile granite crushing plant

Feeding size: ≤800 mm

Discharging size: 2-150 mm

Capacity: 100-580t/h

Get Latest Price

The semi-mobile granite crushing plant is mainly designed to eliminate the problems that occurred in the actual crushing site for users. The integrated unit installation and flexible movement solve the obstacles of crushing operation for the customer, and the operation saves much time and effort.

Video of semi-mobile granite crushing plant

The equipment adopts a half vehicle-mounted structure with tires as the chassis. The flexible collocation allows it to be used in combination with different crushers to meet the different needs of customers.

Customer feedback:

Mr. Paul from the UK sent his feedback: "since the introduction of this semi-mobile granite crushing machine in our plant, the output of our entire production line has stabilized. Our company is very grateful for the benefits this equipment provides for us."

Portable granite crushing plant

Feeding size: ≤1000 mm

Discharging size: 2-180 mm

Capacity: 100-700t/h

Get Latest Price

Based on the traditional semi-mobile crusher and combined with the properties of granite, the portable granite crushing plant is specifically designed. It has significant advantages in both structure and performance, arousing the attention and favor of users at home and abroad.

Video of portable granite crusher

Portable granite crushing plant is mainly composed of four parts: feeding system, crushing system, screening system and conveying system. The purpose of the feeding system is to feed granite materials into the crusher or the screening machine; the crushing system is used to crush granite; the screening system is used to granite gravel screening; and the conveying system is used to transport the finished gravel products.

Customer feedback:

The operation of the mobile crushing station is very stable and effective. The finished material fully meets the various requirements of higher buildings.

Granite crushing production lines

In view of the characteristics of granite, Fote Heavy Machinery also designed a number of fixed granite production lines for customers. The schemes are as follows:

Schemes 1: Vibrating feeder → jaw crusher → cone crusher → vibrating screen

Video of granite gravel production line

Schemes 1 is suitable for the production of large-sized gravel aggregates. The granite production line has low cost and stable operation and is deeply loved by customers.

Schemes 2: Vibrating feeder → jaw crusher → cone crusher → vibrating screen → sand making machine → vibrating screen

Video of granite sand production line

Scheme 2 is suitable for customers who have high requirements for the size and shape of sand and gravel aggregates.

Taking the equipment configuration in the second scheme as an example, the specific crushing process of granite is as follows:

- 1Coarse (primary) crushing: the large stone is uniformly fed into the jaw crusher by the vibrating feeder for coarse crushing.

- 2Secondary crushing: the coarse crushed stone is sent to the cone crusher by a belt conveyor for further fine crushing.

- 3Screening: the finely crushed stone material is sent to the vibrating screen by the belt conveyor.

- 4Sand sand making: the materials which meet the requirement of sand making will be sent into sand making machine for making sand, and others will be returned into cone crusher for re-fine crushing.

- 5Finished screening: the materials processed by the sand making machine are sent to the vibrating screen for screening.

The materials that larger than the particles are returned to the sand making machine and continue to be crushed. Small substances are sent to the sand washing machine for cleaning. The cleaned materials are sent to the finished product pile by the conveyor.

Users' feedback:

The entire granite crushing production line requires almost no manual operation except for the start-up, shutdown and routine maintenance of the equipment.

The finished product of the sand and gravel treated by the production line has a uniform particle size, good granular shape and low output rate of stone powder, which can fully meet the demand of strict requirements.

The entire production line has high production efficiency, low operating cost and high profit.

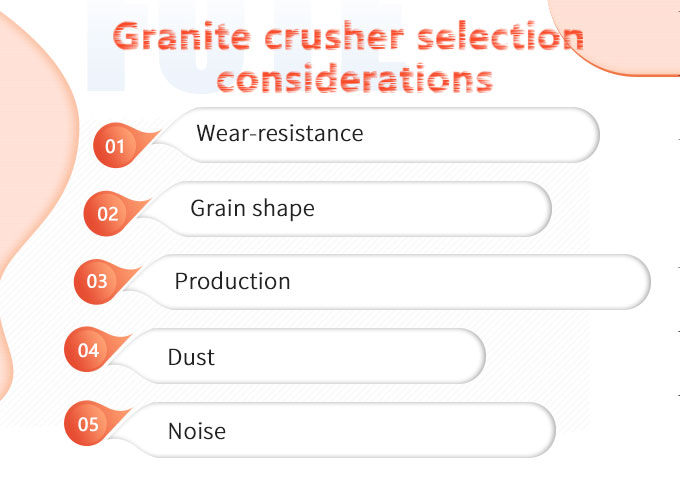

Tips: how to choose (a) suitable granite crusher (crushers)?

Considerations

1. Wear-resistance

Granite is a material with high hardness and high silicon content, which is difficult to crush in actual crushing operations, or it is relatively high in crushing cost. If an unsuitable crusher is selected, the damage speed of the wear parts will be accelerated, and it will need to be replaced even in a few days, and the running cost will increase.

2. Grain shape

Since granite is a brittle material, the improper crusher will increase the content of the needle-like material and increase the internal crack of the finished product, thereby reducing the application range and increasing the production cost.

3. Production

Two or more crusher types will be used in the granite crushing process, so the combination of crusher is especially important. A good production line will make the crushing process run more smoothly, and save labor power and material resources while increasing production.

4. Dust

The crushing of ore cannot avoid the generation of dust. The diffusion of dust will not only pollute the environment, but may cause downtime if it is slightly inadvertent. Therefore, when the crusher is selected, its sealing system and dust control methods should be perfect.

5. Noise

Under the background of environmental protection, reducing noise interference is also one of the channels for environmental protection. Therefore, when choosing a crusher, noise issues should also be taken into account.

The above is the main content of this article. If you have any questions about granite crushing equipment and production lines, please contact Fote Heavy Machinery, and we will reply to you as soon as possible.

Since the establishment of Fote Heavy Machinery, it as the reliable supplier of all kinds of mining machines, has always been aiming at the needs of customers, taking product quality as a development path and focusing on the production of heavy mining machinery and equipment.

Source: https://www.ftmmachinery.com/blog/which-type-of-crusher-is-suitable-for-processing-granite.html

0 Response to "How Easy is It to Crush Granite"

Post a Comment